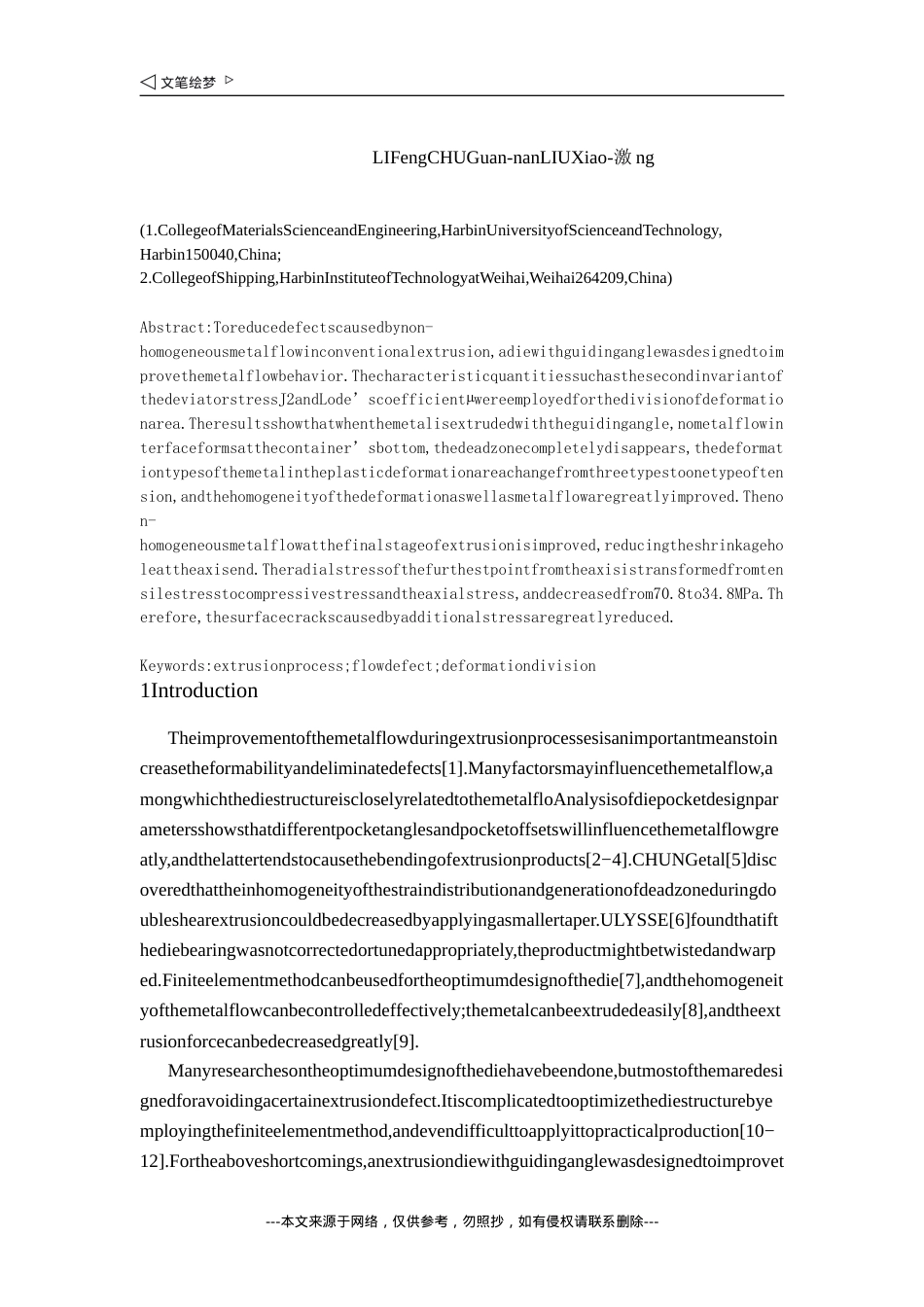

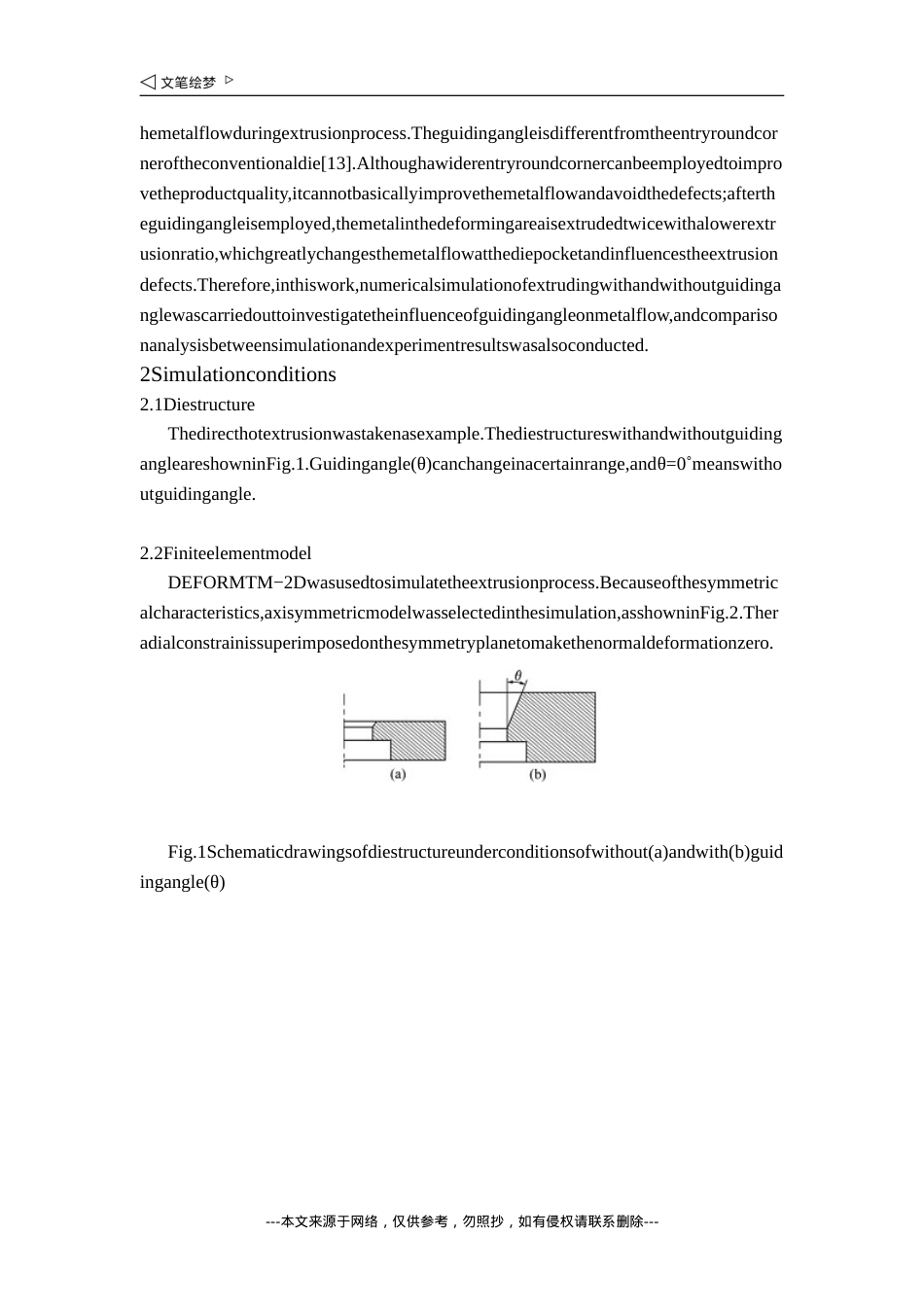

济南大学泉城学院毕业设计外文资料翻译题目铝合金压铸工艺过程中金属流动行为的变形分区专业机械设计制造及其自动化班级07Q3学生张群学号20073006139指导教师陈秀生二〇一一年三月十七日J.Cent.SouthUniv.Technol.(2009)16:0738−0742DOI:10.1007/s11771−009−0122−3Deformationdivisionofmetalflowbehaviorduringextrusionprocessof7075aluminumalloy---本文来源于网络,仅供参考,勿照抄,如有侵权请联系删除---LIFengCHUGuan-nanLIUXiao-激ng(1.CollegeofMaterialsScienceandEngineering,HarbinUniversityofScienceandTechnology,Harbin150040,China;2.CollegeofShipping,HarbinInstituteofTechnologyatWeihai,Weihai264209,China)Abstract:Toreducedefectscausedbynon-homogeneousmetalflowinconventionalextrusion,adiewithguidinganglewasdesignedtoimprovethemetalflowbehavior.ThecharacteristicquantitiessuchasthesecondinvariantofthedeviatorstressJ2andLode’scoefficientµwereemployedforthedivisionofdeformationarea.Theresultsshowthatwhenthemetalisextrudedwiththeguidingangle,nometalflowinterfaceformsatthecontainer’sbottom,thedeadzonecompletelydisappears,thedeformationtypesofthemetalintheplasticdeformationareachangefromthreetypestoonetypeoftension,andthehomogeneityofthedeformationaswellasmetalflowaregreatlyimproved.Thenon-homogeneousmetalflowatthefinalstageofextrusionisimproved,reducingtheshrinkageholeattheaxisend.Theradialstressofthefurthestpointfromtheaxisistransformedfromtensilestresstocompressivestressandtheaxialstress,anddecreasedfrom70.8to34.8MPa.Therefore,thesurfacecrackscausedbyadditionalstressaregreatlyreduced.Keywords:extrusionprocess;flowdefect;deformationdivision1IntroductionTheimprovementofthemetalflowduringextrusionprocessesisanimportantmeanstoincreasetheformabilityandeliminatedefects[1].Manyfactorsmayinfluencethemetalflow,amongwhichthediestructureiscloselyrelatedtothemetalfloAnalysisofdiepocketdesignparametersshowsthatdifferentpocketanglesandpocketoffsetswillinfluencethemetalflowgreatly,andthelattertendstocausethebendingofextrusionproducts[2−4].CHUNGetal[5]discoveredthattheinhomogeneityofthestraindistributionandgenerationofdeadzoneduringdoubleshearextrusioncouldbedecreasedbyapplyingasmallertaper.ULYSSE[6]foundthatifthediebearingwasnotcorrectedortunedappropriately,theproductmightbetwistedandwarped.Finiteelementmethodcanbeusedfortheoptimumdesignofthedie[7],andthehomogeneityofthemetalflowcanbecontrolledeffectively;themetalcanbeextrudedeasily[8],andtheextrusionforcecanbedecreasedgreatly[9].Manyresearchesontheoptimumdesignofthediehavebeendone,butmostofthemaredesignedforavoidingacertainextrusiondefect.Itiscomplicatedtooptimizethediestructurebyemployingthefiniteelementmethod,andevendifficulttoapplyittopracticalproduction[10−12].Fortheaboveshortcomings,anextrusiondiewithguidinganglewasdesignedtoimprovet---本文来源于网络,仅供参考,勿照抄,如有侵权请联系删除---hemetalflowduringextrusionprocess.Theguidingangleisdifferentfromtheentryroundcorneroftheconventionaldie[13].Althoughawiderentryroundcornercanbeemployedtoimprovetheproductquality,itcannotbasicallyimprovethemetalflowandavoidthedefects;aftertheguidingangleisemployed,themetalinthedeformingareaisextrudedtwicewithalowerextrusionratio,whichgreatlychangesthemetalflowatthediepocketandinfluencestheextrusiondefects.Therefore,inthiswork,numericalsimulationofextrudingwithandwithoutguidinganglewascarriedouttoinvestigatetheinfluenceofguidingan...