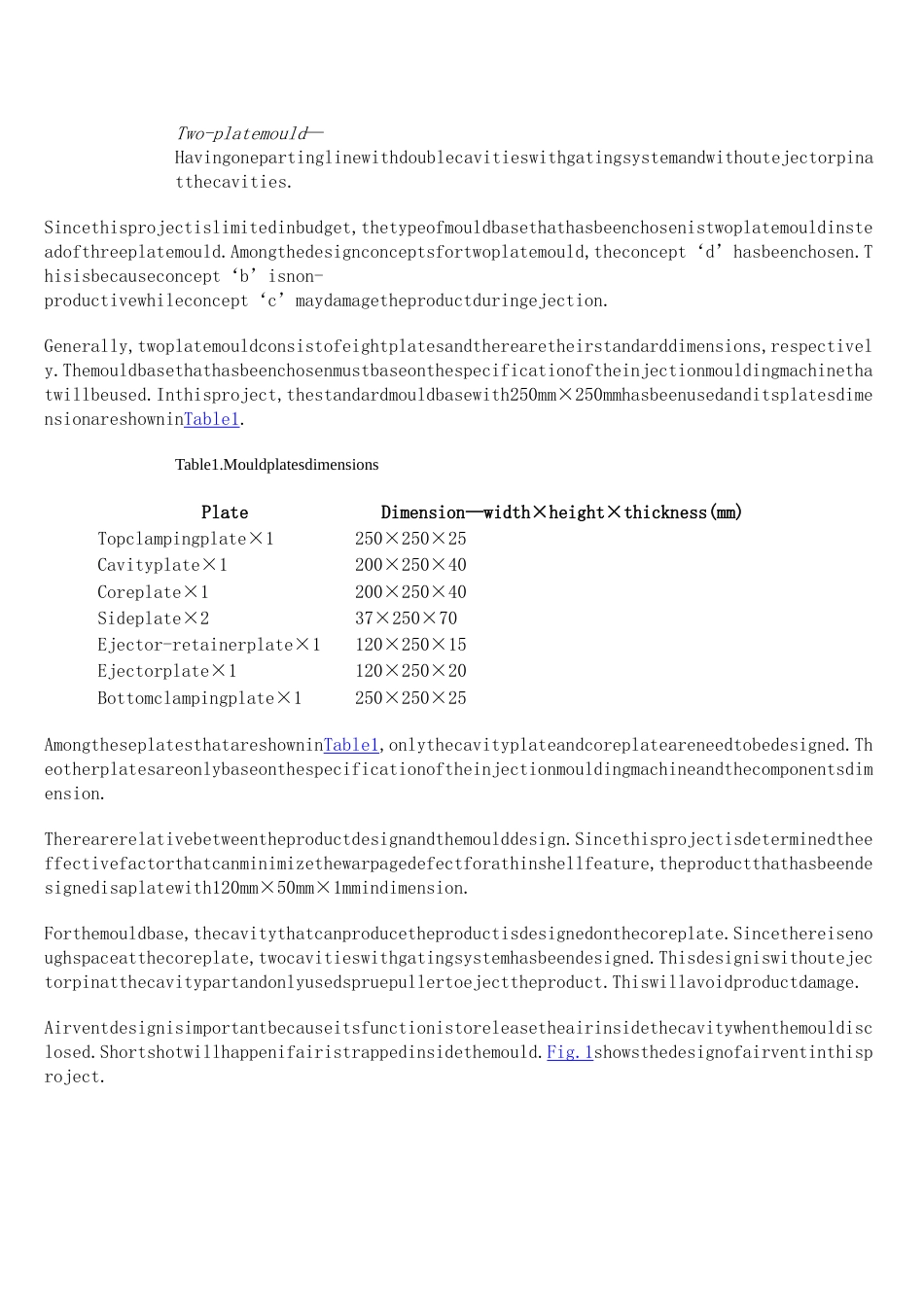

JournalofMaterialsProcessingTechnologyVolume182,Issues1–3,2February2007,Pages418–426TheuseofTaguchimethodinthedesignofplasticinjectionmouldforreducingwarpageS.H.Tang,,Y.J.Tan,S.M.Sapuan,S.Sulaiman,N.Ismail,R.SaminDepartmentofMechanicalandManufacturingEngineering,UniversitiPutraMalaysia,43400Serdang,Selangor,MalaysiaReceived3September2004.Revised27July2006.Accepted10August2006.Availableonline25September2006.dx.doi.org/10.1016/j.jmatprotec.2006.08.025,HowtoCiteorLinkUsingDOICitedbyinScopus(41)PermissionsReprintsAbstractPlasticinjectionmouldingisoneofthemostimportantpolymerprocessingoperationsintheplasticindustrytoday.However,lackofskillinmouldmakingandinjectionmouldingmachinecontrolwillleadtodefectiveplasticproduct.Warpageisonetypeofdefectthatusuallyappearsinproductswiththicknesslessthan1mm.Thisprojectisgoingtofabricateamouldthatproducedathinplatewithdimension120mm×50mm×1mm.Thethinplatewillbeusedforwarpagetesting.Inmouldfabrication,themouldbasethatpurchasewillbemachinedandassembled.Afterthat,themouldisfixedontheinjectionmouldingmachine.Themachinesettingshouldbemadetoproducetheproduct.Then,theproductwillbeusedfortestingontheeffectivefactorsinwarpageproblembyapplyingtheexperimentaldesignofTaguchimethod.Fromtheresults,itshowsthatthemosteffectivefactoronthewarpageismelttemperature.Thefillingtimeonlyslightlyinfluencedonthewarpage.Theoptimumparametersthatcanminimizethewarpagedefectaremelttemperature(240°C),fillingtime(0.5s),packingpressure(90%)andpackingtime(0.6s).KeywordsPlasticinjectionmould;Taguchimethods;Experimentaldesign;Warpage1.IntroductionMouldmakingisanimportantsupportingindustrybecausetheirrelatedproductsrepresentmorethan70%amongthecomponentsinconsumerproducts.Thehighdemandforshorterdesignandmanufacturinglead,gooddimensionalityandoverallquality,andrapiddesignchangeshasbecomethebottlenecksinmouldindustries[1].Itisacomplicatedprocess,andrequiredskilledandexperiencedmouldmaker.Generally,injectionmouldingisoneofthemostimportantpolymerprocessingoperationsintheplasticindustrytoday.Approximatelyone-thirdofallplasticsareconvertedintopartsusinginjectionmoulding[2].Thisisoneoftheprocessesthataregreatlypreferredinmanufacturingindustrybecauseitcanproducecomplex-shapeplasticpartswithgooddimensionalaccuracyandveryshortcycle[3].Typicalexamplesarecasingsandhousingsoftheproductssuchascomputermonitorandmobiletelephone,whichhaveathinshellfeature.Theseproductstendtobecomelighter,thinnerandsmaller.Hence,theinternalcomponentsofproductshavetobepackedintohousing,whichhassmallervolume.Onewaytoincreasethespaceofhousingpartsistoreducethewallthickness.However,theinjectionmouldingoperationbecomesmoredifficultasthewallthicknessofplasticpartsbecomesthinner[4].Thisisbecausethesignificantwarpagedefectwillbeappeared.Toreducethissignificantdefect,testingprocedureregardingtotheeffectivefactorsisrequired.Athinplatewithdimension120mm×50mmand1mmthicknesswillbeproduced.Itisusefortestingontheeffectivefactorstominimizethewarpagedefect.Firstly,fabricatingtheplasticinjectionmouldisneeded.Afterthat,themouldisgoingtobeassembledontheinjectionmouldingmachine.Whenthethinplateshavebeenproduced,theywillbeusedfortestingontheeffectivefactorsinwarpageproblembyapplyingtheexperimentaldesignofTaguchimethod.2.PreparationInfabricatingthemould,somepreparationsareneeded.Thecapabilityofthemac...