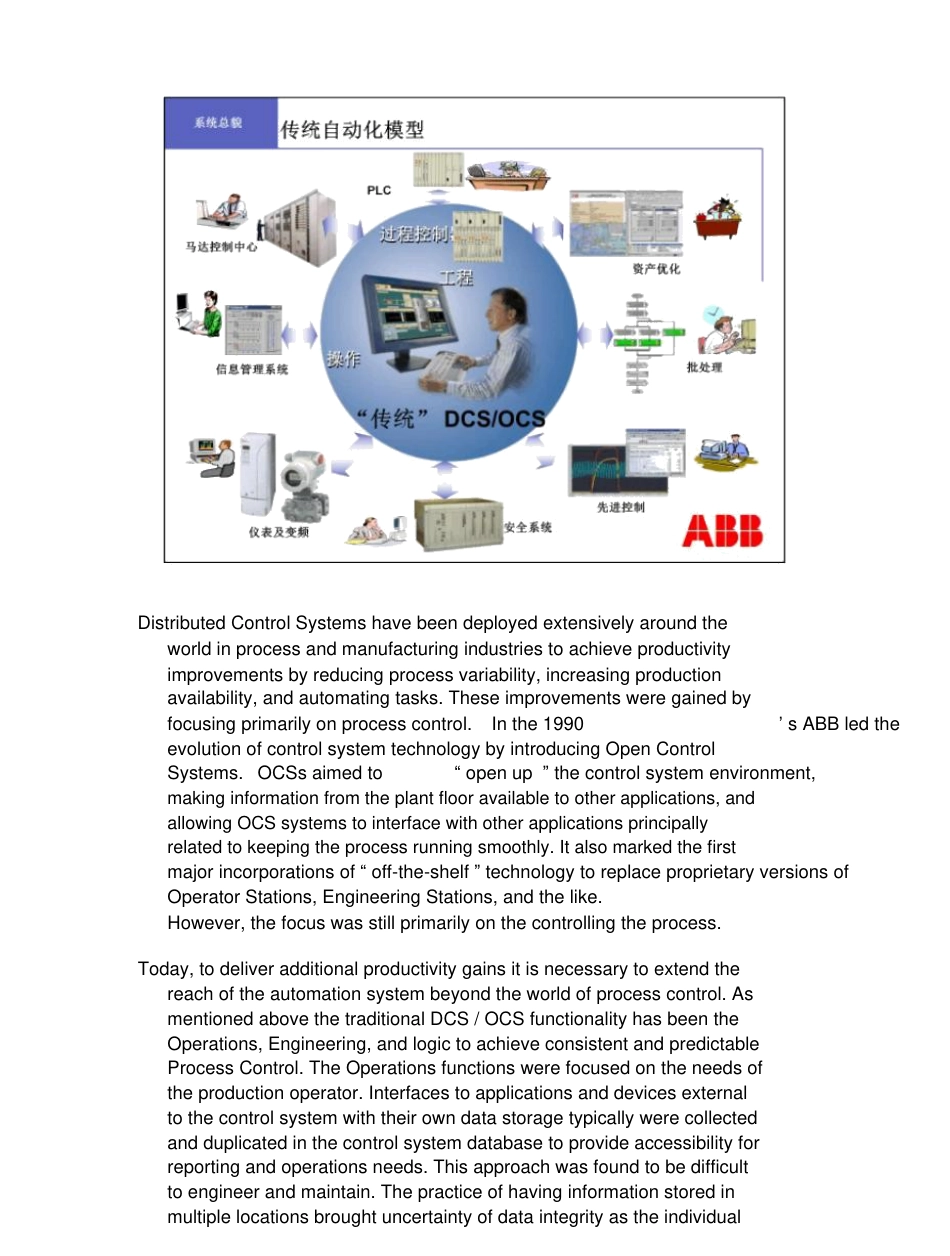

12DistributedControlSystemshavebeendeployedextensivelyaroundtheworldinprocessandmanufacturingindustriestoachieveproductivityimprovementsbyreducingprocessvariability,increasingproductionavailability,andautomatingtasks.Theseimprovementsweregainedbyfocusingprimarilyonprocesscontrol.Inthe1990’sABBledtheevolutionofcontrolsystemtechnologybyintroducingOpenControlSystems.OCSsaimedto“openup”thecontrolsystemenvironment,makinginformationfromtheplantflooravailabletootherapplications,andallowingOCSsystemstointerfacewithotherapplicationsprincipallyrelatedtokeepingtheprocessrunningsmoothly.Italsomarkedthefirstmajorincorporationsof“off-the-shelf”technologytoreplaceproprietaryversionsofOperatorStations,EngineeringStations,andthelike.However,thefocuswasstillprimarilyonthecontrollingtheprocess.Today,todeliveradditionalproductivitygainsitisnecessarytoextendthereachoftheautomationsystembeyondtheworldofprocesscontrol.AsmentionedabovethetraditionalDCS/OCSfunctionalityhasbeentheOperations,Engineering,andlogictoachieveconsistentandpredictableProcessControl.TheOperationsfunctionswerefocusedontheneedsoftheproductionoperator.Interfacestoapplicationsanddevicesexternaltothecontrolsystemwiththeirowndatastoragetypicallywerecollectedandduplicatedinthecontrolsystemdatabasetoprovideaccessibilityforreportingandoperationsneeds.Thisapproachwasfoundtobedifficulttoengineerandmaintain.Thepracticeofhavinginformationstoredinmultiplelocationsbroughtuncertaintyofdataintegrityastheindividualsoftwareapplicationswereadvancedatasynchronouspacesandthecustomizedinterfacesbetweenthemrequiredfrequentmaintenance.WiththeintroductionofSystem800xA,ABB,redefinesthestandardforcontrolsystemfunctionalitybyextendingthereachoftheautomationsystem.FromaninformationaccessandintegrationperspectivetheIndustrialITsystemincorporatesfunctionalityfarbeyondprocesscontrol.Specifically,thesystemincorporatesProcessControl,ProductionManagement,Safety,DiscreteLogicandSequenceControl,AdvancedControl,InformationManagement,SmartInstrumentation,SmartDrivesandMCCs,AssetManagement,andDocumentManagementcapabilitiesinasingularvirtualdatabaseenvironment.TheAspectObjecttechnologyinherenttoIndustrialITprovidestheunifyingplatformbaseallowingeachapplicationtomaintaindatainitssourceapplication,whileprovidingassociationtoaproductionasset.Thisallowsaccesstothedatadirectlyfromitsourceinthecontextoftheproductionassetwithouttheneedtoknowwherethedataiscomingfrom,andwithoutconcernaboutdataintegrityandconcordance.TheabilitytoextendcontrolengineeringstandardstoincorporateandmaintainconnectionstothewealthofIndustrialITapplicationswehavediscussed,andtodeploythesestandardsefficientlyacrossalllikeinstancesisoneoftheuniquecharacteristicsofABB’solution.Thiselegantsolutionaddressestheengineeringandmaintenanceissuesofpastsolutions.ThisnewIndustrialITExtendedAutomationSystem800xAprovidesforasingleoperations,engineering,andinformationmanagementenvironmentforthecompletescopedepictedinthisdiagram.MeettheAspectIntegratorPlatform,arevolutionaryopenarchitectureformanaging,optimizingeverylinkintheenterprisevaluechain.ThispowerfulMicrosoftWindow-basedarchitecturesetsthestandardforeveryIITproductfromABBanditspartners.TheAspectIntegratorPlatformisasoftwarepackagethatintegratesallIndustrialITenabledproductsviatheirAspectObjects,irrespectiveofwheretheymayreside.InthegrandschemeofIndu...