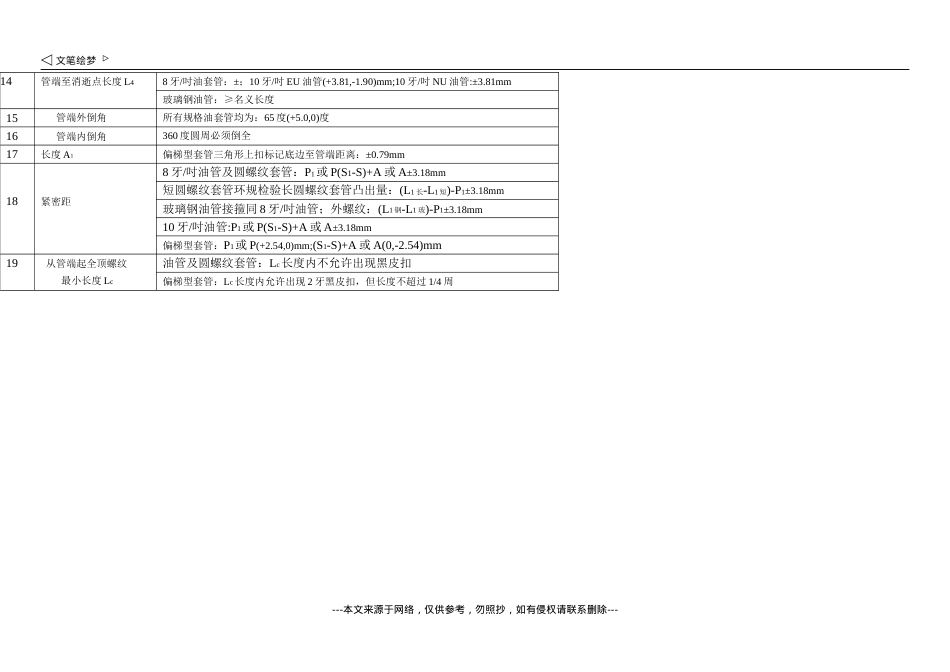

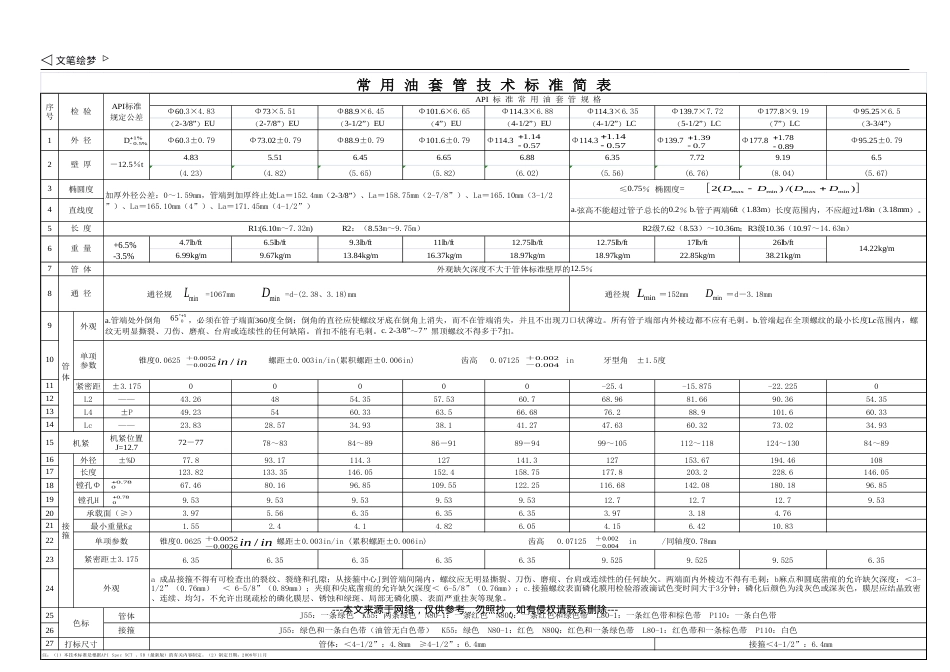

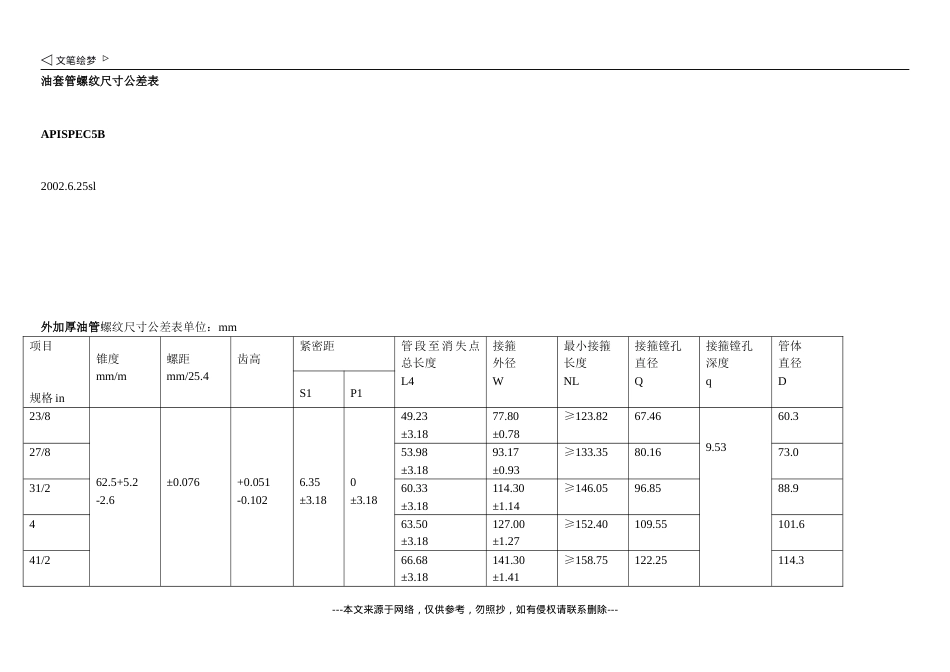

油套管主要检测项目与公差范围序号检测项目公差范围1管体长度L套管Ⅱ类7.62~10.36m;95%及更大车载量允许变化量MAX:1.52m,长度允许MIN:8.53m油管Ⅱ类8.53~9.75m;100%车载量允许变化量MAX:0.61m短节0.61;0.91;1.22;1.83;2.44;3.03;3.66m±7m2管体外径D规格<41/2管子:±0.79;规格≥41/2管子:+1.00%Dmm-0.50%Dmm3管体加厚外径D4规格23/8~31/2管子:+2.38mm-0.79mm规格31/2~4管子:+2.78mm-0.79mm规格>4管子:+2.78mm-0.75%Dmm4管体壁厚t-12.5%,即≥87.5%名义壁厚5管体直度全长;弦高≤0.20%L;管端:下移量≤3.18mm(直尺长度≥1.83m)6接箍外径W油管:±1%W;P110及以下钢级套管:±1%W;但不超过±3.18mm7接箍长度N≥名义长度8接箍镗孔直径Q圆螺纹套管接箍:(+0.79,0)mm9接箍镗孔深度q圆螺纹套管接箍:(+0.79,0)mm10牙型高度偏差油管及圆螺纹套管:(+0.051,-0.102)mm;偏梯型套管及玻璃钢油管:±0.025mm11螺距偏差每25.4mm间距规格≤133/8偏梯型套管及玻璃钢油管:±0.051mm其余油管及套管均为:±0.076mm全长螺距油管及圆螺纹套管:±0.152mm;玻璃钢油管±0.076mm;偏梯型螺纹套管±0.102mm12牙型角偏差油管(含玻璃钢油管)及圆螺纹套管:±1.5度;偏梯型螺纹套管:±1度13锥度油管及圆螺纹套管:62.5(+5.2,-2.6)mm/m,即59.9~67.7mm/m玻璃钢油管:62.5(+2.5,-1.5)mm/m,即61.0~65.0mm/m规格≤133/8偏梯型套管完整螺纹:62.5(+3.5,-1.5)mm/m,即61.0~66.0mm/m规格≤133/8偏梯型套管不完整螺纹:62.5(+4.5,-1.5)mm/m,即61.0~67.0mm/m规格≤133/8偏梯型套管接箍:62.5(+4.5,-2.5)mm/m,6即0.0~67.0mm/m规格≥16偏梯型套管完整螺纹:83.3(+3.5,-1.5)mm/m,即81.8~86.8mm/m规格≥16偏梯型套管不完整螺纹:83.3(+4.5,-1.5)mm/m,即81.8~87.8mm/m规格≥16偏梯型套管接箍:83.3(+4.5,-2.5)mm/m,即80.8~87.8mm/m---本文来源于网络,仅供参考,勿照抄,如有侵权请联系删除---14管端至消逝点长度L48牙/吋油套管:±;10牙/吋EU油管(+3.81,-1.90)mm;10牙/吋NU油管:±3.81mm玻璃钢油管:≥名义长度15管端外倒角所有规格油套管均为:65度(+5.0,0)度16管端内倒角360度圆周必须倒全17长度A1偏梯型套管三角形上扣标记底边至管端距离:±0.79mm18紧密距8牙/吋油管及圆螺纹套管:P1或P(S1-S)+A或A±3.18mm短圆螺纹套管环规检验长圆螺纹套管凸出量:(L1长-L1短)-P1±3.18mm玻璃钢油管接箍同8牙/吋油管;外螺纹:(L1钢-L1玻)-P1±3.18mm10牙/吋油管:P1或P(S1-S)+A或A±3.18mm偏梯型套管:P1或P(+2.54,0)mm;(S1-S)+A或A(0,-2.54)mm19从管端起全顶螺纹最小长度Lc油管及圆螺纹套管:Lc长度内不允许出现黑皮扣偏梯型套管:Lc长度内允许出现2牙黑皮扣,但长度不超过1/4周---本文来源于网络,仅供参考,勿照抄,如有侵权请联系删除---Φ60.3×4.83Φ73×5.51Φ88.9×6.45Φ101.6×6.65Φ114.3×6.88Φ114.3×6.35Φ139.7×7.72Φ177.8×9.19Φ95.25×6.5(2-3/8”)EU(2-7/8”)EU(3-1/2”)EU(4”)EU(4-1/2”)EU(4-1/2”)LC(5-1/2”)LC(7”)LC(3-3/4”)4.835.516.456.656.886.357.729.196.5(4.23)(4.82)(5.65)(5.82)(6.02)(5.56)(6.76)(8.04)(5.67)454.7lb/ft6.5lb/ft9.3lb/ft11lb/ft12.75lb/ft12.75lb/ft17lb/ft26lb/ft6.99kg/m9.67kg/m13.84kg/m16.37kg/m18.97kg/m18.97kg/m22.85kg/m38.21kg/m79外观10单项参数11紧密距±3.17500000-25.4-15.875-22.225012L2——43.264854.3557.5360.768.9681.6690.3654.3513L4±P49.235460.3363.566.6876.288.9101.660.3314Lc——23.8328.5734.9338.141.2747.6360.3273.0234.9315机紧位置J=12.772-7778~8384~8986-9189-9499~105112~118124~13084~8916外径±%D77.893.17114.3127141.3127153.67194.4610817长度123.82133.35146.05152.4158.75177.8203.2228.6146.0518镗孔Φ67.4680.1696.85109.55122.25116.68142.08180.1896.8519镗孔H9.539.539.539.539.5312.712.712.79.53203.975.566.356.356.353.973.184.76211.552.44.14.826.054.156.4210.8322236.356.356.356.356.359.5259.5259.5256.352425管体26接箍273≤0.75%椭圆...