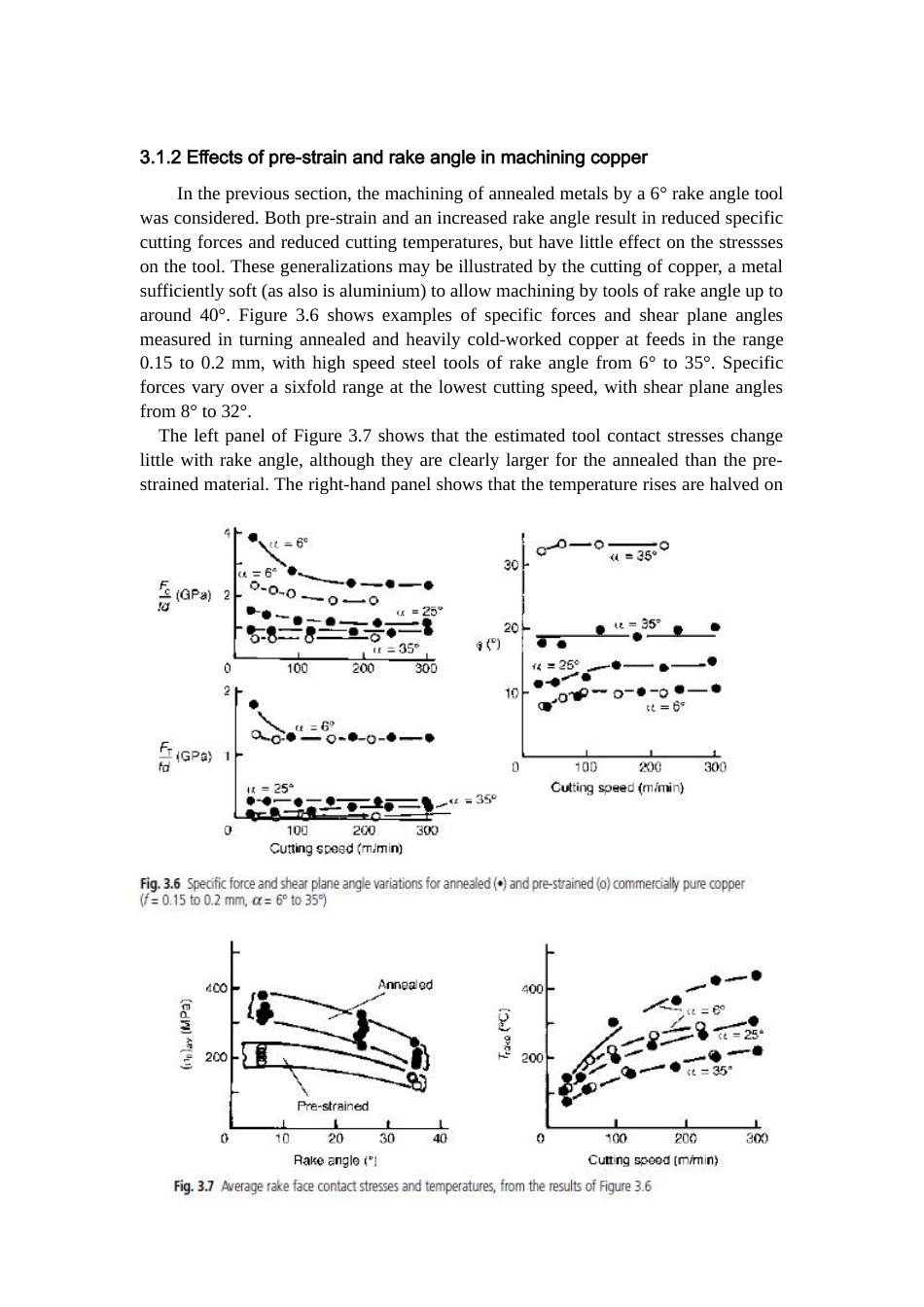

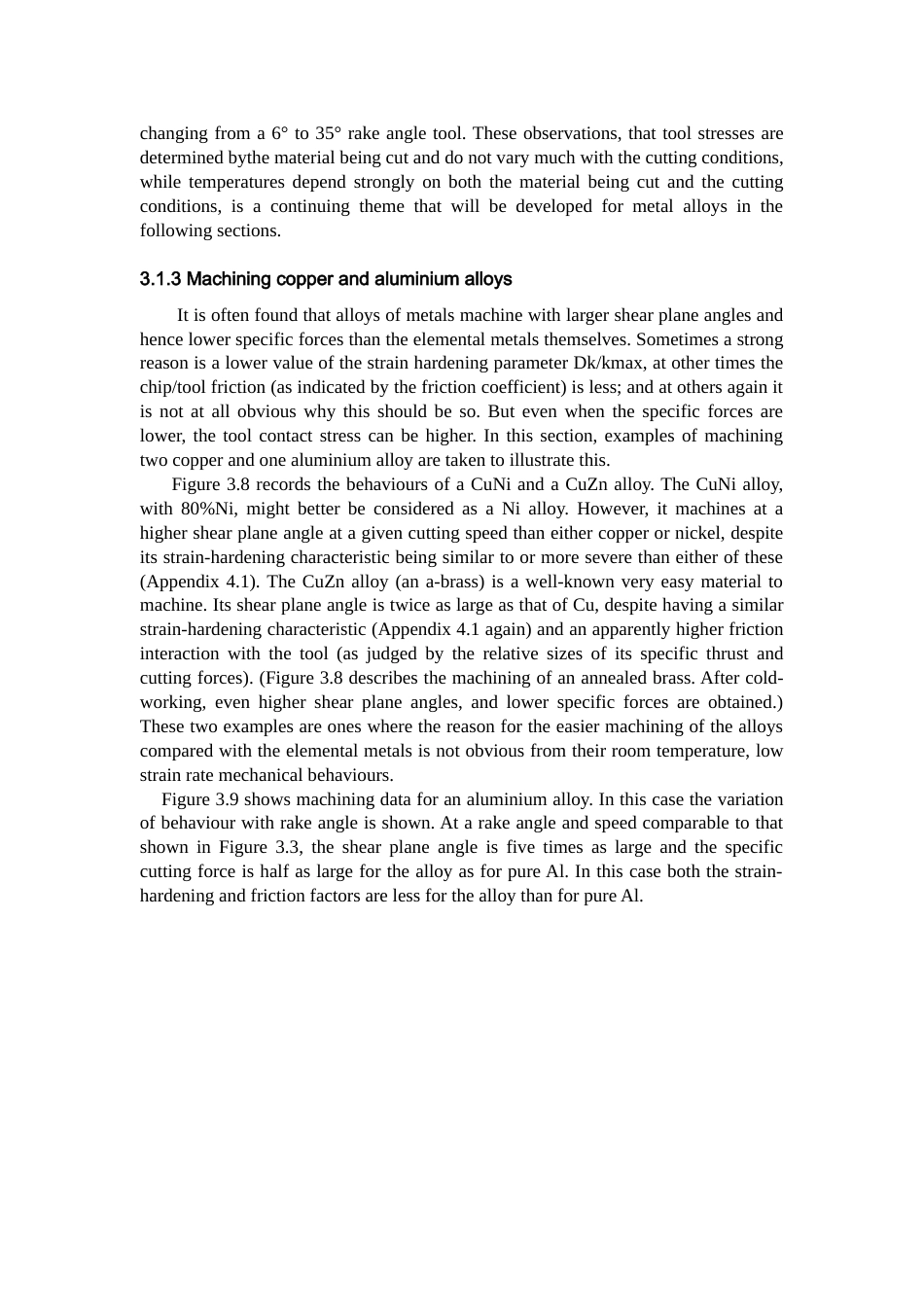

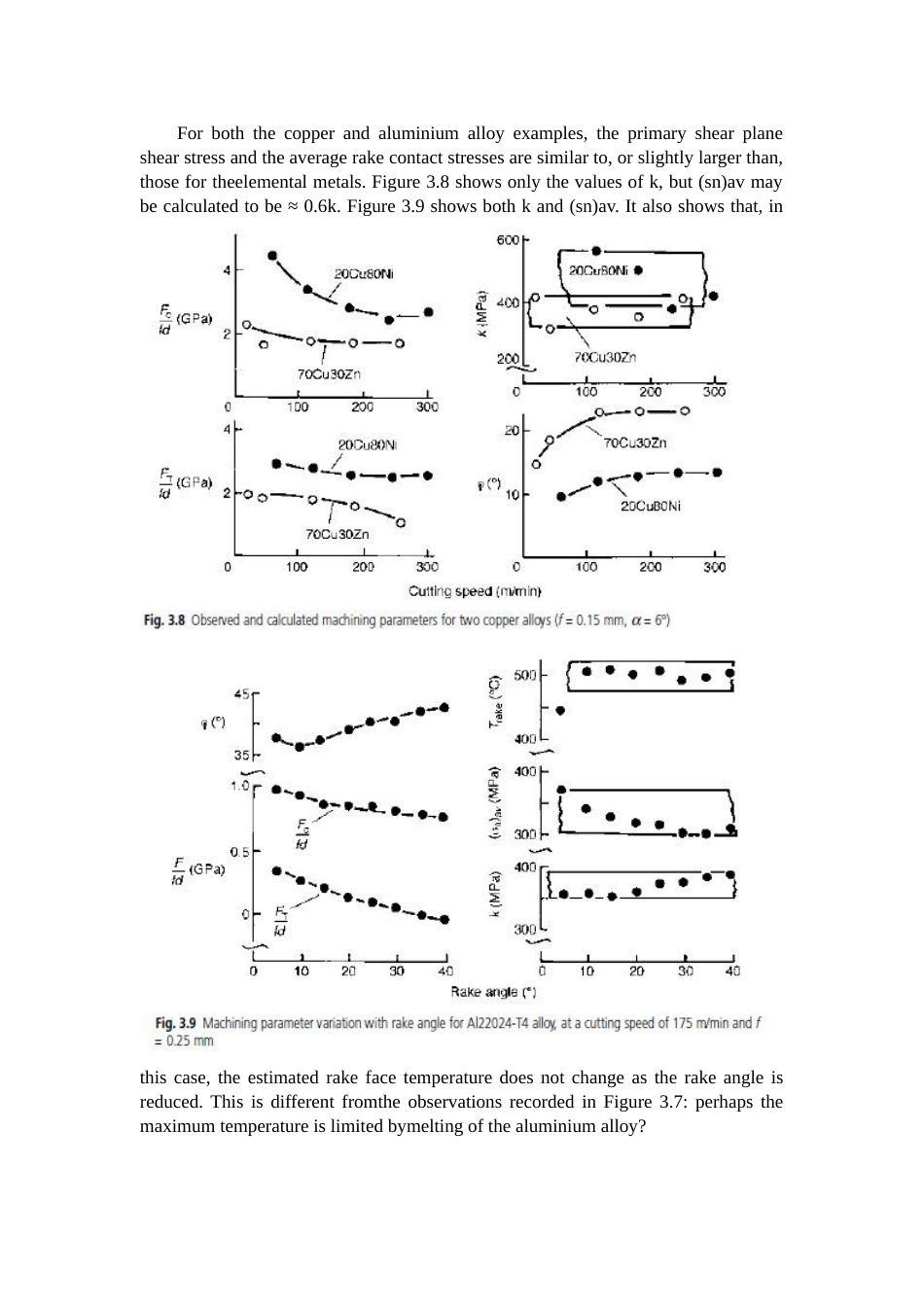

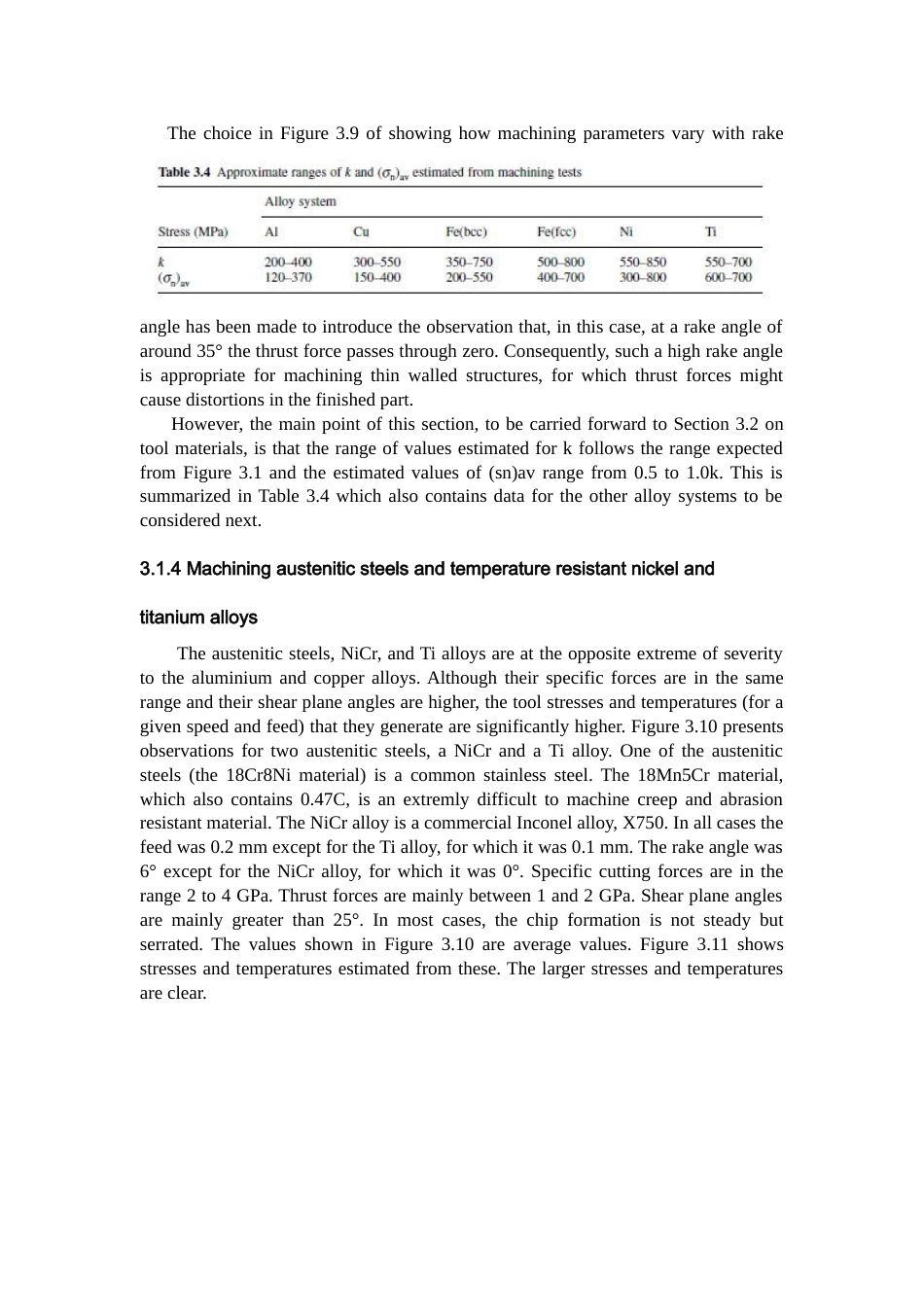

3.1.2Effectsofpre-strainandrakeangleinmachiningcopperIntheprevioussection,themachiningofannealedmetalsbya6°rakeangletoolwasconsidered.Bothpre-strainandanincreasedrakeangleresultinreducedspecificcuttingforcesandreducedcuttingtemperatures,buthavelittleeffectonthestresssesonthetool.Thesegeneralizationsmaybeillustratedbythecuttingofcopper,ametalsufficientlysoft(asalsoisaluminium)toallowmachiningbytoolsofrakeangleuptoaround40°.Figure3.6showsexamplesofspecificforcesandshearplaneanglesmeasuredinturningannealedandheavilycold-workedcopperatfeedsintherange0.15to0.2mm,withhighspeedsteeltoolsofrakeanglefrom6°to35°.Specificforcesvaryoverasixfoldrangeatthelowestcuttingspeed,withshearplaneanglesfrom8°to32°.TheleftpanelofFigure3.7showsthattheestimatedtoolcontactstresseschangelittlewithrakeangle,althoughtheyareclearlylargerfortheannealedthanthepre-strainedmaterial.Theright-handpanelshowsthatthetemperaturerisesarehalvedonchangingfroma6°to35°rakeangletool.Theseobservations,thattoolstressesaredeterminedbythematerialbeingcutanddonotvarymuchwiththecuttingconditions,whiletemperaturesdependstronglyonboththematerialbeingcutandthecuttingconditions,isacontinuingthemethatwillbedevelopedformetalalloysinthefollowingsections.3.1.3MachiningcopperandaluminiumalloysItisoftenfoundthatalloysofmetalsmachinewithlargershearplaneanglesandhencelowerspecificforcesthantheelementalmetalsthemselves.SometimesastrongreasonisalowervalueofthestrainhardeningparameterDk/kmax,atothertimesthechip/toolfriction(asindicatedbythefrictioncoefficient)isless;andatothersagainitisnotatallobviouswhythisshouldbeso.Butevenwhenthespecificforcesarelower,thetoolcontactstresscanbehigher.Inthissection,examplesofmachiningtwocopperandonealuminiumalloyaretakentoillustratethis.Figure3.8recordsthebehavioursofaCuNiandaCuZnalloy.TheCuNialloy,with80%Ni,mightbetterbeconsideredasaNialloy.However,itmachinesatahighershearplaneangleatagivencuttingspeedthaneithercopperornickel,despiteitsstrain-hardeningcharacteristicbeingsimilartoormoreseverethaneitherofthese(Appendix4.1).TheCuZnalloy(ana-brass)isawell-knownveryeasymaterialtomachine.ItsshearplaneangleistwiceaslargeasthatofCu,despitehavingasimilarstrain-hardeningcharacteristic(Appendix4.1again)andanapparentlyhigherfrictioninteractionwiththetool(asjudgedbytherelativesizesofitsspecificthrustandcuttingforces).(Figure3.8describesthemachiningofanannealedbrass.Aftercold-working,evenhighershearplaneangles,andlowerspecificforcesareobtained.)Thesetwoexamplesareoneswherethereasonfortheeasiermachiningofthealloyscomparedwiththeelementalmetalsisnotobviousfromtheirroomtemperature,lowstrainratemechanicalbehaviours.Figure3.9showsmachiningdataforanaluminiumalloy.Inthiscasethevariationofbehaviourwithrakeangleisshown.AtarakeangleandspeedcomparabletothatshowninFigure3.3,theshearplaneangleisfivetimesaslargeandthespecificcuttingforceishalfaslargeforthealloyasforpureAl.Inthiscaseboththestrain-hardeningandfrictionfactorsarelessforthealloythanforpureAl.Forboththecopperandaluminiumalloyexamples,theprimaryshearplaneshearstressandtheaveragerakecontactstressesaresimilarto,orslightlylargerthan,thosefortheelementalmetals.Figure3.8showsonlythevaluesofk,but(sn)avmaybecalculatedtobe≈0.6k.Figure3.9showsbothkand(sn)av.Italsoshowsthat,inthiscase,theestimatedrakefacetemperaturedoesnotchangeastherakeangleisreduced.Thisisdifferentfro...