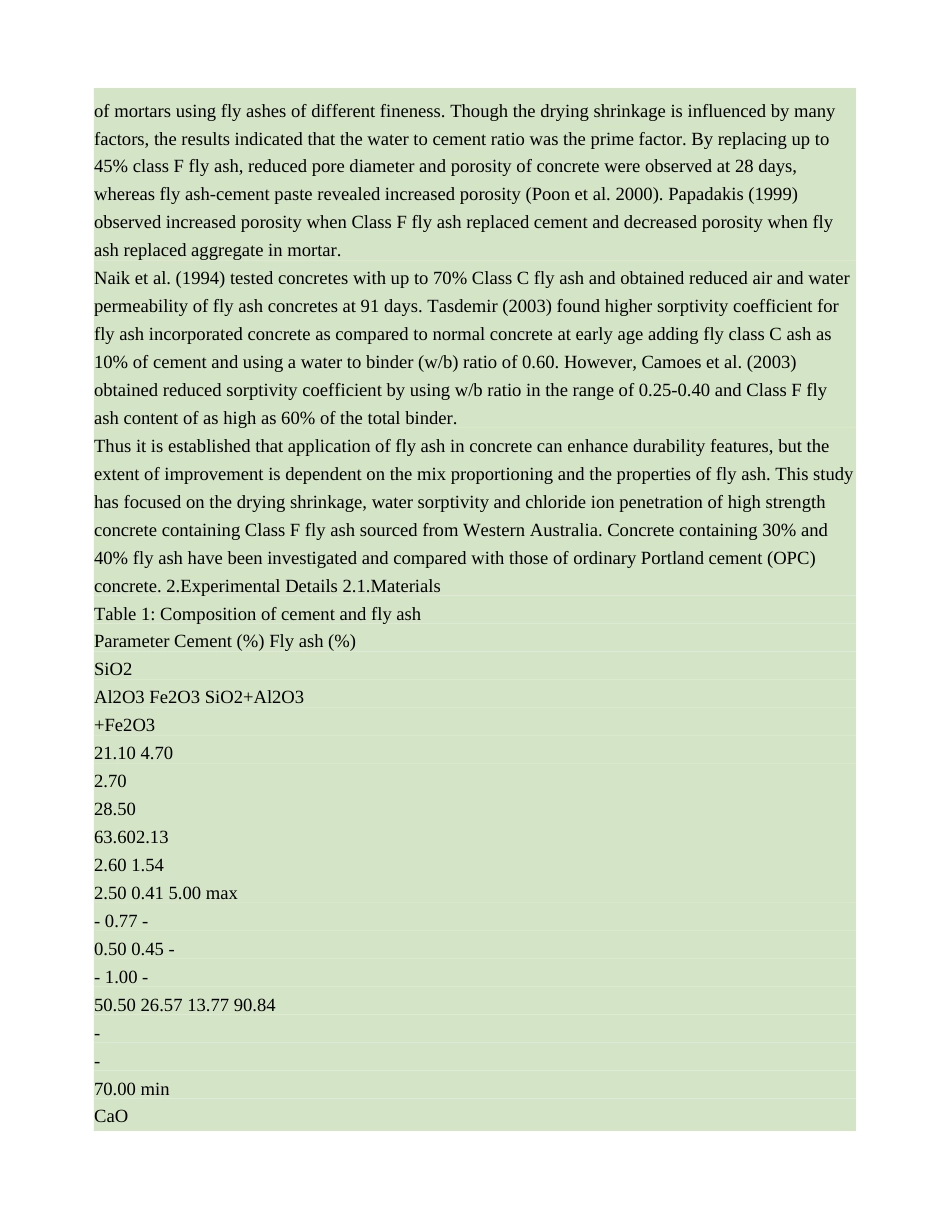

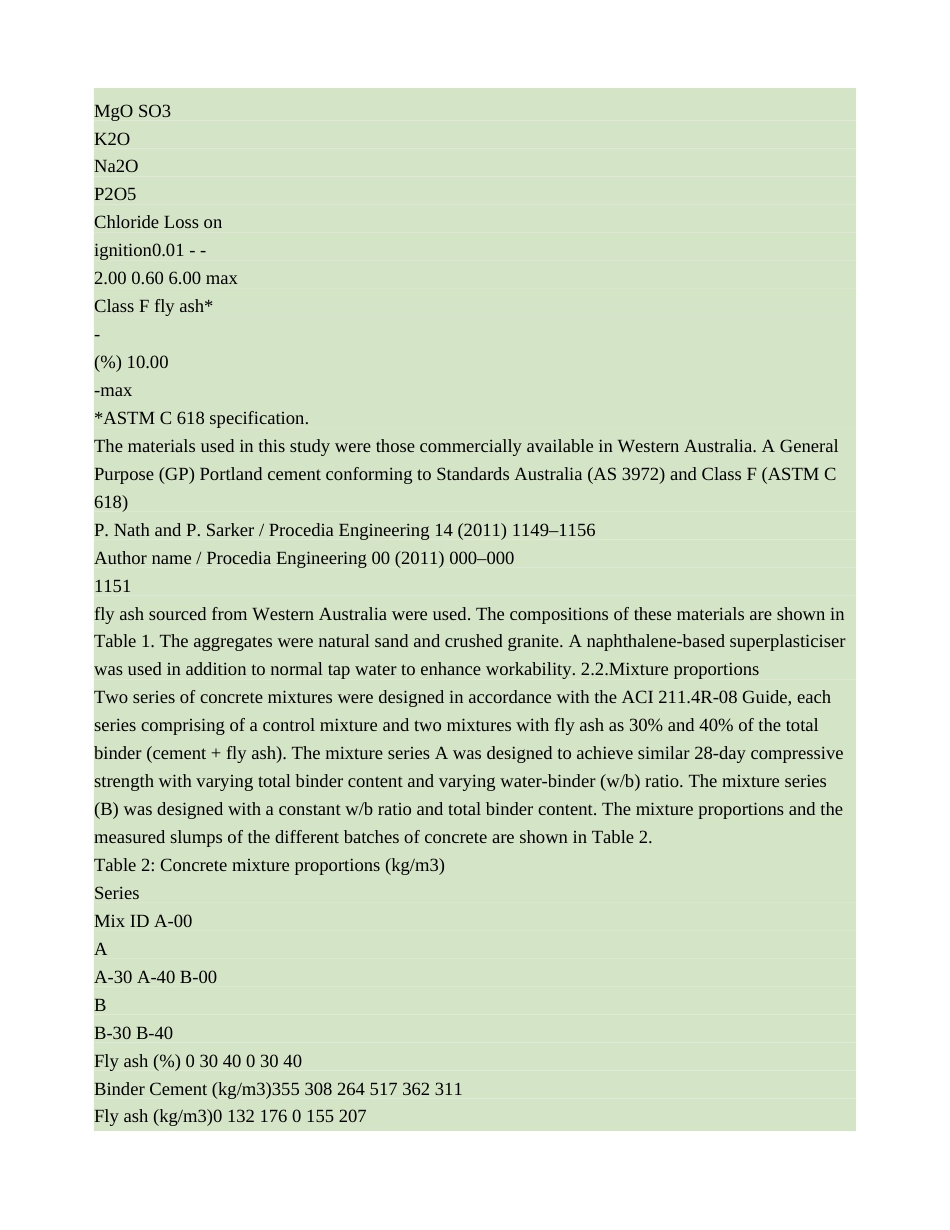

Availableonlineatwww.sciencedirect.comvailableonlineatwww.sciencedirect.comProcediaEnineerinwww.elsevier.com/locate/procediaProcediaEngineering00(2011)000–000ProcediaEngineering14(2011)1149–1156TheTwelfthEastAsia-PacificConferenceonStructuralEngineeringandConstructionEffectofFlyAshontheDurabilityPropertiesofHighStrengthConcreteP.Nath1a,P.Sarker1b1DepartmentofCivilEngineering,CurtinUniversity,Australia.AbstractUtilizationofflyashasasupplementarycementitiousmaterialaddssustainabilitytoconcretebyreducingtheCO2emissionofcementproduction.Thepositiveeffectsofflyashasapartialreplacementofcementonthedurabilityofconcretearerecognizedthroughnumerousresearches;however,theextentofimprovementdependsonthepropertiesofflyash.Inthisstudy,durabilitypropertiesofhighstrengthconcreteutilizinghighvolumeClassFflyashsourcedfromWesternAustraliahavebeeninvestigated.Concretemixtureswithflyashas30%and40%oftotalbinderwereusedtocastthetestspecimens.Thecompressivestrength,dryingshrinkage,sorptivityandrapidchloridepermeabilityoftheflyashandcontrolconcretespecimensweredetermined.The28-daycompressivestrengthoftheconcretemixturesvariedfrom65to85MPa.Theflyashconcretesamplesshowedlessdryingshrinkagethanthecontrolconcretesampleswhendesignedforthesame28-daycompressivestrengthofthecontrolconcrete.Inclusionofflyashreducedsorptivityandchlorideionpermeationsignificantlyat28daysandreducedfurtherat6months.Ingeneral,incorporationofflyashaspartialreplacementofcementimprovedthedurabilitypropertiesofconcrete.©2011PublishedbyElsevierLtd.Keywords:Chloridepermeability,dryingshrinkage,durability,flyash,sorptivity1.IntroductionConcreteisthemostwidelyusedconstructionmaterialinthemodernworld.Thedurabilityofconcreteisamajorconsiderationinitsapplicationinaggressiveenvironmentsforalongservicelife.Concreteincorporateslargeamountofnaturalresourcesasaggregatesandcementwithwater.Cementproductionconsumeshugeenergyandcausesabout7%oftotalgreenhousegasemissionintheworld(Malhotra2002).abCorrespondingauthor:Email:pradip.nath@postgrad.curtin.edu.auPresenter:Email:p.sarker@curtin.edu.au1877–7058©2011PublishedbyElsevierLtd.doi:10.1016/j.proeng.2011.07.14411502P.NathandP.Sarker/ProcediaEngineering14(2011)1149–1156Authorname/ProcediaEngineering00(2011)000–000Hence,utilizationofsupplementarycementitiousmaterialssuchasflyash,slagandsilicafumeisbeingresearchedextensivelyoverthelastfewdecadestoenhancedurabilityandsustainabilityofconcrete.Flyashisaby-productofthecombustionofpulverisedcoalandisapozzolanicmaterial.WhenitismixedwithPortlandcementandwater,itgeneratesaproductsimilartothatformedbycementhydrationbuthavingadensermicrostructurethatislesspermeable.Theflyashreplacementlevelas15-25%isrecommendedforhighstrengthconcrete(ACICommittee2112008),whileitcanbeusedasmorethan50%oftotalbinderfornormalstrengthconcrete(Caretteetal.1993).CanadaCenterforMineralandEnergyTechnology(CANMET)isthepioneerintheresearchonhigh-volumeofFlyashconcrete.NumerousreportsshowedtheconcretehavinghighvolumeofClassFflyashexhibitedexcellentmechanicalanddurabilitypropertiessuchaslowpermeabilitytochlorideionsandotheraggressiveagents(Langleyetal.1989;Mathotra1990).Caoetal.(1996)reportedflyashconcretesyieldingbetterresultinchloridediffusionandsulphateattackthanOPCconcrete.Flyashinconcretereducesdryingshrinkage(Atis2003),thusgeneratesfewercrackswhichensuregreaterresistancetode...